So the first "current" post is about... this  :

:

Brembo link: Rear Billet Brake Master Cylinder With Reservoir

Brembo RACING Rear Billet Brake Master Cylinder With Reservoir Product code: XA2.C6.10

The reason why I choose this Rear Master Cylinder (eventhough it cost more than other Brembo RACING Rear Billet MC) was because, it has the opening on top of it's billet body that I can use to connect a brake reservoir.

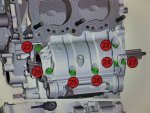

This is a BIG GAMBLE on my part though... I contacted motorquality, the main Brembo distributor in Italy, I also contacted Brembo USA and other Brembo authorized dealers in USA or in Europe (even in Asia), and none of them really knew what this gold bolt for.

All of them also told me that there is no way I can connect an outside brake reservoir to this MC.

However, after taking careful looks at the shape of the master cylinder body, I was 95% confident that the holes that this bolts cover is located behind the main cylinder tube where the piston push the fluid to the caliper. Just like where in normal master cylinder, it is where you connect the rubber hose to the reservoir. And turn out I am CORRECT .

.

I check manually after I received it and "everything is going to be allright"

The other Brembo RACING master cylinders do not have this bolts/hole thus making them not compatible with outsider reservoir.

The question then, why I want an outside reservoir? Well because:

a. I don't want to remove the MC each time I need to fill the brake fluid due to the position of the MC on Panigale V4 rear sets.

b. I like the design and color of this specific master cylinder, very simple and classic

c. I also has invested a lot of time and customization effort to have a Ducati by Rizoma rear brake reservoir, I love the way it looks so I want to keep the reservoir

In the next few days, I will post more CUSTOMIZATION that I am making to this master cylinder, yes, that's right, even this MC will be MODIFIED .

.

More pictures below:

Brembo link: Rear Billet Brake Master Cylinder With Reservoir

Brembo RACING Rear Billet Brake Master Cylinder With Reservoir Product code: XA2.C6.10

The reason why I choose this Rear Master Cylinder (eventhough it cost more than other Brembo RACING Rear Billet MC) was because, it has the opening on top of it's billet body that I can use to connect a brake reservoir.

This is a BIG GAMBLE on my part though... I contacted motorquality, the main Brembo distributor in Italy, I also contacted Brembo USA and other Brembo authorized dealers in USA or in Europe (even in Asia), and none of them really knew what this gold bolt for.

All of them also told me that there is no way I can connect an outside brake reservoir to this MC.

However, after taking careful looks at the shape of the master cylinder body, I was 95% confident that the holes that this bolts cover is located behind the main cylinder tube where the piston push the fluid to the caliper. Just like where in normal master cylinder, it is where you connect the rubber hose to the reservoir. And turn out I am CORRECT

I check manually after I received it and "everything is going to be allright"

The other Brembo RACING master cylinders do not have this bolts/hole thus making them not compatible with outsider reservoir.

The question then, why I want an outside reservoir? Well because:

a. I don't want to remove the MC each time I need to fill the brake fluid due to the position of the MC on Panigale V4 rear sets.

b. I like the design and color of this specific master cylinder, very simple and classic

c. I also has invested a lot of time and customization effort to have a Ducati by Rizoma rear brake reservoir, I love the way it looks so I want to keep the reservoir

In the next few days, I will post more CUSTOMIZATION that I am making to this master cylinder, yes, that's right, even this MC will be MODIFIED

More pictures below: