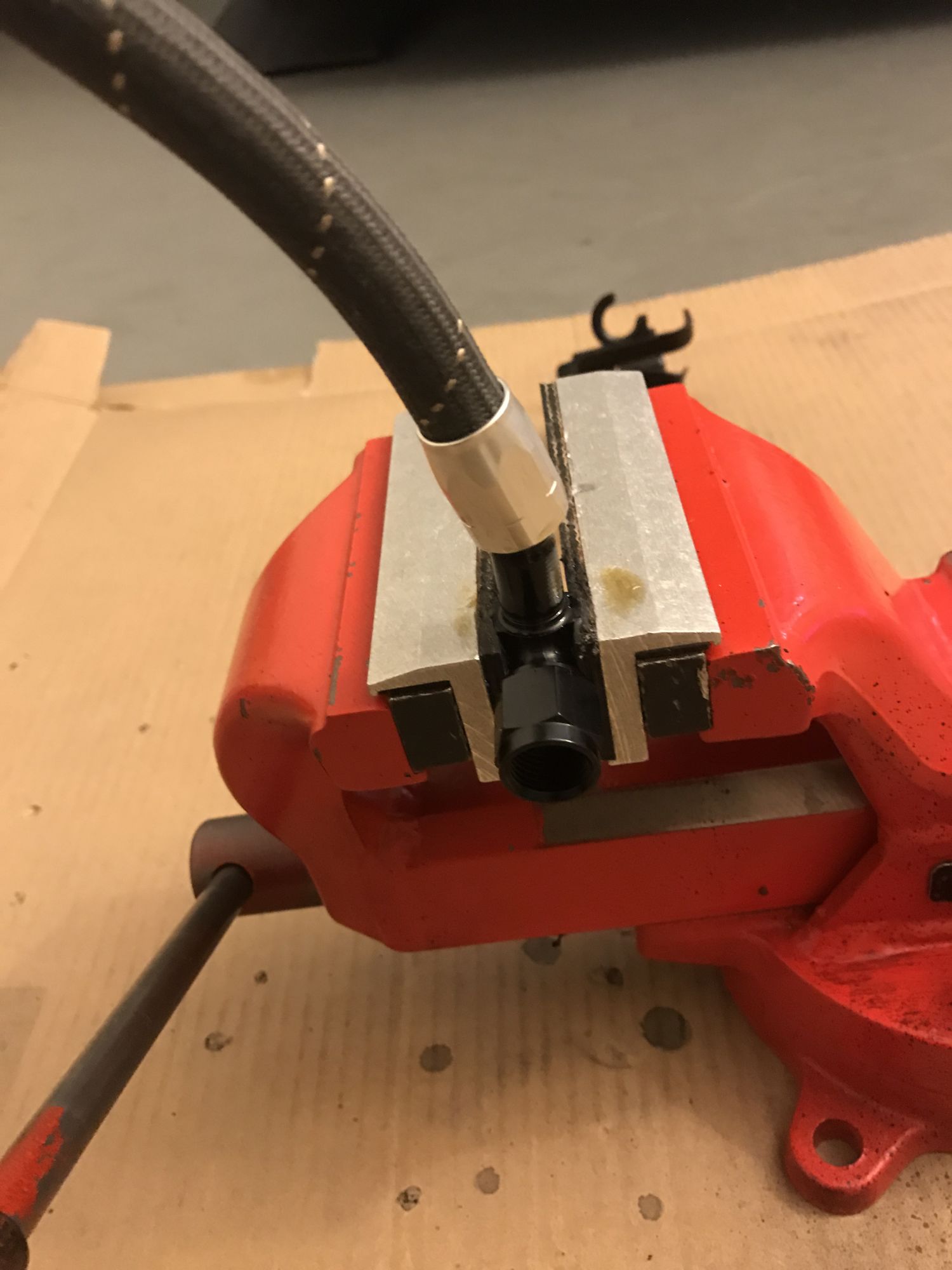

All those black banjos adapter are Goodridge Stainless Steel Shadow Line (Black finish). NO Aluminum fittings are allowed here

Well, except the Aluminum Chase Bay "F" shape distributor since those will be securely mounted, plus the 3 brake line coming into it acting as further bracing,

and the Aluminum Staubli's since those are obviously engineered (meaning shape/thickness/diameter) differently.

When I was selling Goodridge decades ago, I never spec aluminum banjos adapter (in braking application) for my customer even when they asked me too.

Initially, I was thinking of buying the Stainless Steel finish Goodridge Banjo Adapter, but one of those came only in 20 degree, and I found the Shadow Line banjos came with 15 degree angle.

Thus meaning less protruding on the ABS module.

Then I also realized the Black Banjo Adapter finish will provide great contrast between the Stainless Steel surface background of the ABS module and the Titanium Silver of the ProTi,

not to mention in between those black banjo, will be POLISHED Copper Washer. This will make great color combination.

While I am here might as well post the part# for everyone that is interested to use this,

so here are the Goodridge Banjo's adapter Part# used on the ABS module (note the "CBK" on the part number means C(Stainless Steel) BK(Black)):

a. Part#B593-03CBK, Goodridge Shadow Universal Adapters, 15 degree, Stainless Steel, Black, 10mm Banjo, -3 AN Male Threads,

Qty needed 2 pieces for the 2 right ports on the ABS module that goes to the rear braking system

Goodridge Shadow Universal Adapters B593-03CBK

b. Part#B597-03CBK, Goodridge Shadow Universal Adapters, 15 degree/Side Bend, Stainless Steel, Black, 10mm Banjo, -3 AN Male Threads,

Qty needed 1 pieces for the second port from the left on the ABS module that goes to front Master Cylinder

Goodridge Shadow Universal Adapters B597-03CBK

c. Part#B592-03CBK, Goodridge Shadow Universal Adapters, Straight, Stainless Steel, Black, 10mm Banjo, -3 AN Male Threads,

Qty needed 1 pieces for the first port from the left on the ABS module that goes to the front Caliper

Goodridge Shadow Universal Adapters B592-03CBK

d. Part#B594-03CBK, Goodridge Shadow Universal Adapters, 45 degree, Stainless Steel, Black, 10mm Banjo, -3 AN Male Threads,

Qty needed 1 pieces for the Oberon Clutch Slave Cylinder

Goodridge Shadow Universal Adapters B594-03CBK

Well, except the Aluminum Chase Bay "F" shape distributor since those will be securely mounted, plus the 3 brake line coming into it acting as further bracing,

and the Aluminum Staubli's since those are obviously engineered (meaning shape/thickness/diameter) differently.

When I was selling Goodridge decades ago, I never spec aluminum banjos adapter (in braking application) for my customer even when they asked me too.

Initially, I was thinking of buying the Stainless Steel finish Goodridge Banjo Adapter, but one of those came only in 20 degree, and I found the Shadow Line banjos came with 15 degree angle.

Thus meaning less protruding on the ABS module.

Then I also realized the Black Banjo Adapter finish will provide great contrast between the Stainless Steel surface background of the ABS module and the Titanium Silver of the ProTi,

not to mention in between those black banjo, will be POLISHED Copper Washer. This will make great color combination.

While I am here might as well post the part# for everyone that is interested to use this,

so here are the Goodridge Banjo's adapter Part# used on the ABS module (note the "CBK" on the part number means C(Stainless Steel) BK(Black)):

a. Part#B593-03CBK, Goodridge Shadow Universal Adapters, 15 degree, Stainless Steel, Black, 10mm Banjo, -3 AN Male Threads,

Qty needed 2 pieces for the 2 right ports on the ABS module that goes to the rear braking system

Goodridge Shadow Universal Adapters B593-03CBK

b. Part#B597-03CBK, Goodridge Shadow Universal Adapters, 15 degree/Side Bend, Stainless Steel, Black, 10mm Banjo, -3 AN Male Threads,

Qty needed 1 pieces for the second port from the left on the ABS module that goes to front Master Cylinder

Goodridge Shadow Universal Adapters B597-03CBK

c. Part#B592-03CBK, Goodridge Shadow Universal Adapters, Straight, Stainless Steel, Black, 10mm Banjo, -3 AN Male Threads,

Qty needed 1 pieces for the first port from the left on the ABS module that goes to the front Caliper

Goodridge Shadow Universal Adapters B592-03CBK

d. Part#B594-03CBK, Goodridge Shadow Universal Adapters, 45 degree, Stainless Steel, Black, 10mm Banjo, -3 AN Male Threads,

Qty needed 1 pieces for the Oberon Clutch Slave Cylinder

Goodridge Shadow Universal Adapters B594-03CBK