Prepping the tank for fitting. Aside from the fuel pump which is best left in place, I had to replace all the fittings before the assembly could go back on the bike. This meant renewing several items where necessary and carefully manoeuvreing it back onto the frame without scratching anything.

Main fuel line feed pipe went on first. New "Norma" clamp ensures a leak free seal. The only thing to watch out for here is that you orientate the angle of the pipe correctly, else it is a PIA to connect it to the airbox fuel inlet

feed.

That done, next up were the support brackets, Swiss cheese original bolts replaced with A2 stainless items. Locktited and torqued as per factory spec.

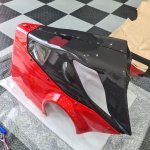

Dual lock pads and new fairing grommets in place on each side. Instead of the goop OEM white lithium grease, I bought some red rubber grease which will prevent these grommets from being pushed out when the fairing pins pass through them.

New dual locks for atop the tank. The backing on these is a total mare to remove, so I slit them with a surgical blade in order to peel it off. Once on the bike they aint moving, so you need to ensure you position them accurately before you commit.

Once the rear grommets were fitted (where the tank bolts to the rear subframe), all that remained was to offer it up to the bike, reconnect the earth lead, fuel pump electrical connector and breather lines, then bolt it back into place. Next up was the underseat bracket, fuel inlet hose clamp where it attached to the airbox inlet feed and fuel filler assembly.

The filler plate is held on with four bolts, so again these were replaced with stainless items. The plate is orientated in such a way that you need to ensure the two bleed holes line up correctly, to allow the venting system to work. before bolting it down. Finally the DP filler cap went on next and job done.