Ok, long time no write ups, doesn't meant that I haven't done anything.

After fork cartridge project, I decided to do something about my v4evo tail light. Turn signals was totally useless in daylight.

Opening that taillight unit was tricky, cos didn't know where to pull and is there some clips that holds, but patience and good plastic levers did the trick.

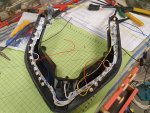

I bought some 3w amber leds and started to plan how to connect and mount them.

After many calculations I decided to use 12 leds per side, 2x6 in series. That give me good value of light and safe current with full voltage 14.3 when engine running. No resistors.

At this point, all was clear to me, but then the problems started.

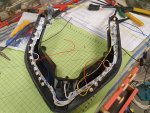

I used hard wire to solder them in series, but then leds take too much space and that midlle section (with brake leds) didn't fit.

So new plan, and new mounting style.

This was good and everything fits now. But my bad luck continues.

I used hot glue to instantly glue leds and sealbond under leds. I was using too little that bond under led and I made short circuit to original system, new leds need to be top of original led strip resistors at some locations.

So one oe led fries and I had hard time to find spare. At last I managed to change it and was able to continue.

First attempt to glue it back together was disaster. Too much sealbond and it was everywhere. I take it a part right away when bond was still fresh.

Second attempt was success.

But unfortunately my broblems didn't end there.

I continue this horror story tomorrow.