Weekend update

:

Today, I decided to work on the tie locking all the wiring and I start with the rear subframe wiring.

But first, I tie lock the wiring that goes to the rear subrame but start on the top of the airbox:

Oh, I also improvised a bit to secure the bypass plug for the secondary air injection connector:

Then secure the wiring loom to the subframe starting from the first securing point nearer to the engine and goes to the back:

Then I need to figure out where I am going to put the 2 Bike Sport Development rear Ohlins EC stock by pass module...

After looking at several alternative, I decided, first I need to run the wire to the back of the subframe, right under the main rear subframe wiring loom:

Then I install the extension wire that came with the kit from Bike Sport Development all the way to the back, u-turn and goes to the right side of the subframe:

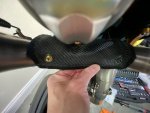

After that I am using the 3M Velcro to secure those modules to the right side of the Ilmberger carbon fiber rear subframe cover:

I choose this location for this module because it is quite protected from rain, and it still have plenty of airflow since this modules might get hot. I also don't want to put it right above the rear manifold (there is space there),

because that area might be too hot and not much air flow.

After that, I tightened the left rubber/plastic bracket for the CAN connector and also the rear tail light connector:

Plus, I install the by-pass plug for the rear taillight, because the bike cannot have the taillight when the dealer installing the Akrapovic Up-map. Not due to technical issue, but due to the regulation that the up-map is only for track use bike.

Oh, my heart skip a beat when I realize that I never test the rear subframe key... meaning I am not sure whether I can fit a key there with the Termignoni silencer bracket near it...

but to my relief, there is plenty of space to insert the key

:

But then, my heart skip another beat because I realize the location of the O2 sensor on the SC-Project WSBK manifold is totally different than the location with the stock exhaust, and the length of the cable from the O2 sensor might not be enough to meet with the connector from the bike wiring loom side...

Furthermore, I am also not sure if the Ducati UP-MAP (Akrapovic) will require the removal of the O2 sensor...

So, I study the Installation Manual of the Ducati Akrapovic full system, and I found out the Akrapovic Full System still require the stock O2 sensor to be mounted and connected to the bike wiring loom.

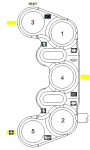

The only strange (well maybe NOT IDEAL is the right word) for the Ducati Akrapovic Full System is, the O2 sensor only connect to 1 cylinder per bank.

For the rear cylinder bank, it connect to the RIGHT rear cylinder, and for the front cylinder bank, it connect to the RIGHT front cylinder.

Meaning the Left Cylinder of the front and rear bank does not have any O2 sensor monitoring.

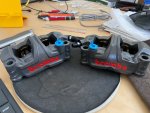

The SC-Project WSBK exhaust on the other hand had 6 location, 4 per each bank and 2 more for either rear or front cylinder banks.

I decided to follow the stock exhaust configuration and install the 2 stock O2 sensors to measure both the rear and front cylinder banks on the SC-Project WSBK exhaust.

I think this is better than the way Ducati Akrapovic system O2 sensor location, according to Ducati Akrapovic install manual, although it might have holes for each cylinder banks, but I don't want to open the bubble wrap of the pipes to check since I already pack it well last time.

However, this means, I still need to REROUTE the wiring from the bike wiring loom for the rear cylinder bank O2 sensor from the original location near the rear exhaust manifold to the LEFT Side of the bike.

I found the best route is through the side of the front frame, but the space there is very tight and the connector size is quite big that it took me around 30 minutes to juggle and struggle and finally find a way to make it pass through.

That include took of one of the airbox securing clamp, as you can see in the picture below, and that plastic connector is the big connector I am talking about:

after that, don't forget to push the airbox clamp back in secure position:

And here are the pictures that show where the connector from the wiring loom will meet it's counterpart from the O2 sensor. By the way at the bottom of this picture you also see the connector from the bike wiring loom for the front cylinder bank O2 sensor, which now has to go underneath the oil sump across the engine since the O2 sensor for the front cylinder bank is now located on the right side of the bike, right below the right rear set.