Ok, so far, I have not touch my bike (this weekend), but I plan to start installing airbox after I have my late breakfast today

I was spending a lot of time yesterday and this morning to find solutions to replace the STREET version of the Left Handle Bar SWITCHES and I finally found one

So, I love my Right Handle Bar Switches made by Bike Sport Development UK. In fact, this is the only style that I like.

I don't like the Jetprime, CNC Racing, and Ducabike because their offering have a "rough machine surface finish style", and I prefer a smooth finish surface style.

Plus, only Bike Sport Development can supply your switch with ALL BLACK color switches, while the other brand offer in the M&M candy color.

For switches, I really only want BLACK color to make it looks more "Professional", this is just personal preferences.

Please note that this has nothing to do with quality, I am sure Jetprime, CNC Racing, and Ducabike are all very good quality switches. Beside from my understanding, all the switches were made by Jetprime as the OEM manufacturer for CNC Racing and Ducabike anyway, so for sure quality is great.

This is just because I only like the styling of the Bike Sport Development UK switches, and actually only the Type C switches. They just look special to my eyes

So upon discussion with Bike Sport Development, initially we are going to see if I can get enough people to do a group buy on this forum so Bike Sport Development can develop a STREET Version of their Left Handle Bar switches.

They currently already have a RACE version of their left handle bar switches which eliminate the horn, hazard, light and turn signal function.

However, I want those street function to be available, thus the custom development needed.

Ducati Panigale V4 Left Handle Bar Switches is NOT just a mechanical switches but they work using LIN Bus (Local Interconnected Network) protocol, so there is a need to perform SOFTWARE Development.

This alone will cost approximately 5,000 poundsterling before even calculating the production cost. Because this is basically a NEW standalone product development from the ground.

So this mean, we will need a group buy of perhaps 30 to 50 people, and I don't think I will be able to find 50 people to buy this STREET Left Handle Bar Switches.

Here is how the LIN modules look like:

So, I almost gave up... because of course I could not justify myself to funds the 5,000 poundsterling development cost by myself nor will I ever get an over 50 person group buy...

but... almost gave up doesn't mean I did...

so I keep my brain processing and processing and processing

suddenly I have this new and last idea...

So Jetprime (left picture) and Ducabike (right picture) have a ROAD/Street version of their Ducati Panigale V4 Left hand Switch.

I realized that their LIN module is the black box (inside orange circle) in these pictures below:

Because I really don't think there is any LIN electronic circuit inside the aluminum housing based on this picture below, where we can see 2 bare wires (white and brown wires) peeking from the handlebar through-hole:

The 2 pictures below show how Jetprime and Ducabike switches look like from the rear side. Jetprime/Ducabike design is based on 8 switches (7 function switches + 1 switch to toggle between the dual mode).

And these pictures below show the button layout and designations of the Ducabike and Jetprime ROAD/STREET version Left Handle Bar switches:

Based on all the above, I believe I should be able to use Bike Sport Development's switches in combination with Jetprime/Ducabike LIN module.

So I discuss my findings above with Bike Sport Development, and they believe this is also doable,...

However, it is not 100% sure that this will work, since nobody ever done this before.

Plus, I have to perform the INTEGRATION myself because obviously, Bike Sport Development cannot use other company's LIN module.

Because of that, I will purchase RAW but CUSTOM Switches from Bike Sport Development, and INTEGRATE it myself to the LIN module of the Jetprime switches.

It's a gamble, but I think I have a good Risk to Reward Ratio, not to mention, I can be the first (and maybe the only) person in the world to have the Bike Sport Development UK Left Handle Bar Street Version Switches for Panigale V4

I mean, who else is willing to go to this much trouble... err.. wait, this is DUCATImodified, I forget that many members here are as passionate or even more passionate than me so... I took it back...

but at least, I had a head start in doing this

I am now thinking of using Jetprime LIN module and wired it to Bike Sport development's current 7 switches type C Clutch mount

BD_SW_7BC_04 for Panigale V4 but mount it with the Type G generic Clamp.

Then to the right of the

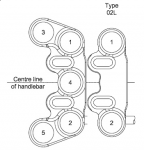

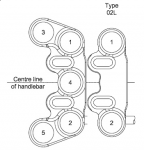

BD_SW_7BC_04, I willl use a Generic but CUSTOM Type 02L switches with CL-A clamp attached to my RCS 16 Corsa Corta clutch master cylinder.

We now have 9 switches total, but one of the switch on the Type 02L can be a duplicate function.

I prefer the top switch on the Type02L for Hazard function while the bottom switch for "DUAL Mode Switch". And, of course, very important is the custom laser marking on the Type 02L to mark these 2 functions.

Oh, of course, I want the color of all the switches to be all BLACK color.

Below is the diagram for illustration on the positioning of the switches on the left handlebar.

A few minutes ago, I just order the Jetprime Street Version Left Handle Bar Switches so the INTEGRATION Project just officially started, please stay tune