My younger son and I start working on the new 748RS swing arm today.

So, Ducati no longer sell the tools to install the needle bearing (chain side), and I really looks all around the world and just can't find anyone selling it.

But I manage to buy the Ducati Special Tools to install the right side regular bearing (wheel side):

I watch this restoration video that

@Andy7 kindly pointed out to me a few months ago to learn how he manage to install the needle bearing without any Ducati Special Tools:

Turn out he is just using the simple washer with bolt and nut method. However after careful observation, I notice he did not do it properly on the needle bearing side.

First this needle bearing will have a rubber seal on both sides of it, but in this video, it is clear he did not install the 2 rubber seal. Not to mention the way he tightened the washer means the needle bearing outer surfaces were flush with the surface of the swing arm, while if you want to install the rubber seals, then the needle bearing need to go in 4mm further below the surface of the swing arm.

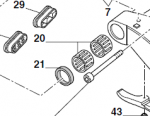

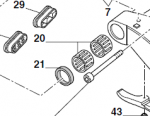

This diagram said it all (Part# 21 is the rubber seal I am talking about):

So, I collected all the long bolt and nut and different sizes of washers that I can use to make the needle bearings installation to be PERFECT without Ducati Special Tools:

First, I asked my younger son to freeze all the bearings and I am heating up the swing arm:

Then first step is to install the needle bearing on the inner side:

As you can see below, the needle bearing is going in:

Then I keep changing either the nut/bolt or washers to push it in further:

Next, do the same thing but for the outer side needle bearing:

Now the methods above only able to make the needle bearing flush with the surface of the swing arm, but now I need to make them go in more (about 4mm) to accommodate the rubber seals.

So first, I need to CUT the swing arm bushing/spacer that have the right diameter to push the needle bearing outer race further in:

Now it is at the PERFECT Length. I already bought a new bushing anyway, so this bushing is expendable for tooling. If you don't cut it, then it is a bit too long and won't work:

I start pushing both bearings to the center until both touch at the center. This is quite tricky because the distance is so tight that I need to go back and forth between left and right side before I manage to get them perfectly centered:

Next installing the rubber seal. In the picture below, you can see that I am inserting the inner rubber seal first (that rubber seal showing at the forefront of the picture is just illustration and it will be for the outer side):

This is how the inner rubber seal looks like after flush with the surface of the swing arm:

Then install the outer rubber seal:

PERFECT

Then I realized, I will need grease for all these bearings (and swing arm pivot). Turn out it is another of that SPECIAL Shell Gadus Grease C...

which of course I haven't bought... After doing more research the Shell Gradus Grease C with is Retinax LX2 has now change name to SHELL GADUS S3 V220C 2

and luckily available at Amazon:

https://www.amazon.com/gp/product/B01BU2980O/

Ok, now I will continue with installing the regular bearing on the wheel side of the swing arm...

:

:

:

: