Thanks for this information Craig, this is very helpful. FYI, I am very interested in Composite, especially Carbon Fiber material because I am hoping I can work in this area in the next few years. Don't know what or how to get there yet, but in the processI’m no subject matter expert, but I have seen that carbon fiber bonding in other applications, specifically in aftermarket automotive wheels. I exchanged emails with the founder of Litespeed Racing regarding possible purchase for my big turbo Toyota Supra. He said:

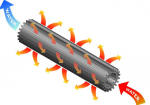

“Hello Craig, please see the below testing done by a 3rd party, that is not affiliated with LitespeedRacing. In their testing, they found almost 500% increase in strength by bonding 3 layers of carbon fiber the an aluminium bar. The bar that they used for testing is a good representation of the effects of adding carbon fiber to the barrel of a wheel, as the average forged wheel has a barrel thickness of 4mm, and the aluminium bar they tested was very similar in thickness.”

He included this image:

View attachment 4201

Carbon fiber is composite because it has the fiber (carbon) and the bonding (resin), all this fiber is fully encapsulated in the resin. By adding carbon fiber layer on the aluminum, its become a composite of composite which now combine the aluminum and carbon fiber properties all in one.

However, to completely get the full benefit, the aluminum will need to be fully encapsulated with the carbon fiber, and the very important process is the bonding. So, maybe there is some substance (adhesive) that can successfully bond a flat smooth surface of aluminum to the carbon fiber, but I think it will be more strong bonding if

in the sprocket case, the base aluminum is like a human skeleton completely encapsulated by tissue (carbon fiber).

Because if you are bonding a flat smooth surface of aluminum to another flat surface of carbon fiber with just an adhesive, of course it will be stronger if you do the break testing from just 1 direction (that benefit most from the fiber orientation), but how about on a sprocket where the force is the spinning and sometimes a bit sideways due to the swing arm flex.

it too much flex (and vibration) and heat and oil/chain grease and water, the glue might be undone and there goes the reinforcement strength. But if you fully encapsulated then the carbon fiber and aluminum skeleton will not be separated unless the carbon fiber cracked.

Hey, maybe I can produce this carbon fiber sprocket... hmmm,