HKMP7's V4S Journal

- Thread starter HKMP7

- Start date

Your friend is awesome, in friendship and ideasRandom awesomeness

So I had this large random package in my mailbox. It was from one of my biker buddies.

Opened it up and found this.

He works for the city so these are actual street signs and here's the best part. EPIC

If he happened to press another "print" button and made another copies of the sign, please kindly let me know

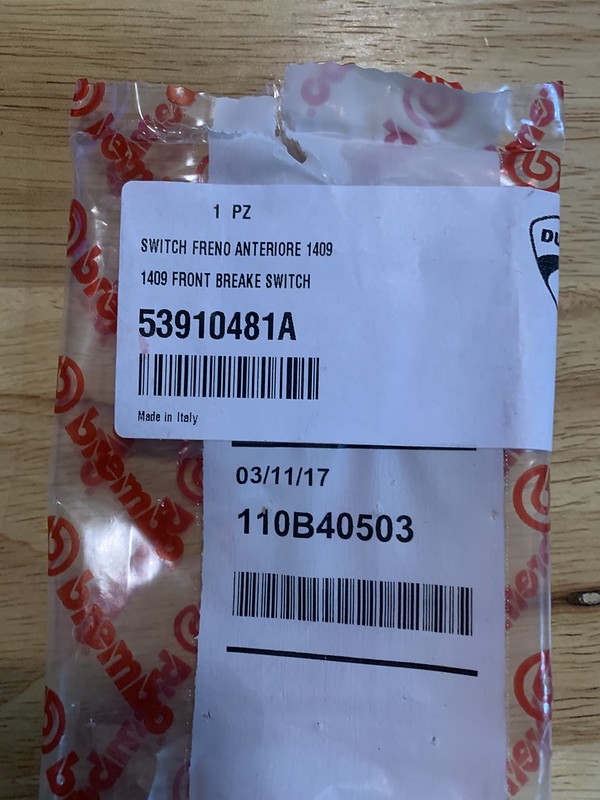

Brembo GP4 MS ti diet.

Got the calipers cleaned up and ceramic coated almost ready for install.

Swapped the bleeders for Ti versions.

Stock bleeders 11g each

Ti bleeder 6g each

I modified the rubber bleeder caps. I dont like the "laynard" they come with so I cut them off. I think it looks cleaner and they are on so tight its never gonna come off anyway.

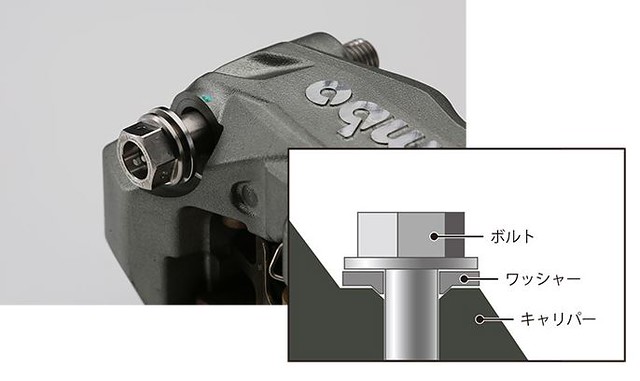

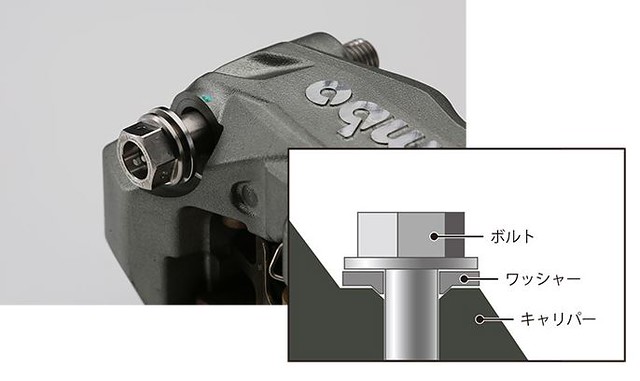

Aella caliper washers

These are interesting I don't think they will do much for "centering" the caliper but I'll try them. I mainly got them because they will keep the caliper bolts from scratching the caliper body.

I found it interesting these Motogp calipers have something similar "built in". Wonder why.

You can check it them out in this thread.

ducatimodified.com

ducatimodified.com

Got the calipers cleaned up and ceramic coated almost ready for install.

Swapped the bleeders for Ti versions.

Stock bleeders 11g each

Ti bleeder 6g each

I modified the rubber bleeder caps. I dont like the "laynard" they come with so I cut them off. I think it looks cleaner and they are on so tight its never gonna come off anyway.

Aella caliper washers

These are interesting I don't think they will do much for "centering" the caliper but I'll try them. I mainly got them because they will keep the caliper bolts from scratching the caliper body.

I found it interesting these Motogp calipers have something similar "built in". Wonder why.

You can check it them out in this thread.

The Obtainable Brembo GP4-MS, GP4-RR, GP4-PR, GP4-RS, GP4-RX and Unobtainable Brembo new GP4 caliper

First the UNOBTAINABLE GP4 Caliper (yes the model code is just GP4 without any alphabet behind it): I actually contacted Brembo USA about this caliper because I love the cooling fins design and they told me: Brembo works very closely with MotoGP to constantly improve the brakes. We see the...

Last edited:

From my guessing, the reason why the MotoGP calipers have those "washers" is to create a harder surface for the many bolting and unbolting during many races. An aluminum surface of the caliper will be softer than the Titanium bolts, thus it will deform over time with many bolting and unbolting (rotary action of the titanium bolt head). That washers also distribute the clamping force of the titanium bolts at much wider area.I found it interesting these Motogp calipers have something similar "built in". Wonder why.

You can check it them out in this thread.

The Obtainable Brembo GP4-MS, GP4-RR, GP4-PR, GP4-RS, GP4-RX and Unobtainable Brembo new GP4 caliper

First the UNOBTAINABLE GP4 Caliper (yes the model code is just GP4 without any alphabet behind it): I actually contacted Brembo USA about this caliper because I love the cooling fins design and they told me: Brembo works very closely with MotoGP to constantly improve the brakes. We see the...ducatimodified.com

From the color of that washers, I think they are most likely also made of Titanium.

I thought the same thing. What's interesting too the centering they talk about.From my guessing, the reason why the MotoGP calipers have those "washers" is to create a harder surface for the many bolting and unbolting during many races. An aluminum surface of the caliper will be softer than the Titanium bolts, thus it will deform over time with many bolting and unbolting (rotary action of the titanium bolt head). That washers also distribute the clamping force of the titanium bolts at much wider area.

From the color of that washers, I think they are most likely also made of Titanium.

Attachments

-

9.9 KB Views: 2

I thought about some of those.Ti pistons for the MS

View attachment 3695

For now I’m going to run the standard pistons. Maybe that can be a end of the season upgrade. @Keith97 did you replace yours? Is it a pretty straightforward install. Thanks

Yeah, nothing to it other than using compressed air to get the old pistons out. Main advantage is it keeps the heat out of the caliper and fluid much better than the stock alum.I thought about some of those.

For now I’m going to run the standard pistons. Maybe that can be a end of the season upgrade. @Keith97 did you replace yours? Is it a pretty straightforward install. Thanks

Tsaico

FOUNDING Member

So pretty! I want some!Ti pistons for the MS

View attachment 3695

craig bush

Well-known member

Interesting info re: caliper piston material

“I have been interested in caliper pistons for some time now and have been looking at the parts available in the market and tried to reach some conclusions about the 'best' materials.

To start with I think it is important to review the objectives we have with regard to the duty of the brakes and what is required from the pistons.

There is a view that the 'job' of a caliper seal is not only to prevent fluid leakage but to retract the piston when pressure is released as this stops the pad from rubbing on the disc and is good for economy.

I have to say that I don't agree with this analysis and that pad retraction is generally a bad thing and that the effect of this action is similar to 'pad knock off' and increases pedal travel.

It is common to fit race calipers with either residual springs behind the pistons or with low pressure check valves to eliminate this problem.

The seal is always responsible for a small amount of piston retraction and this will vary depending on the surface finish of the piston, the stored energy in the seal due to radial compression and even the fluid used to lubricate the piston during initial assembly.

Using brake fluid, for example, increases seal friction compared to the correct assembly grease and this influence will last for many thousands of miles.

I believe that good quality pistons should have a high level of surface finish, relatively low thermal coefficient of expansion(TCE), Have relatively low Heat Transfer Coefficient (HTC),be relatively corrosion resistant and have good wear resistance.

If we review the materials that have been discussed then the basic properties are easy to find but there are influences that also need to be considered .

1. Conventional Steel

Typically chrome plated, modest expansion, modest heat transfer, huge amounts of comparative test data available and in every sense have stood the test if time.

A conventional medium carbon steel in an 'as rolled' condition is unlikely to have adequate wear resistance.

The quality in terms of dimensional control and surface finish of some aftermarket parts is questionable but Porsche Caliper Pistons supplied by BudWeg seem to be reasonable and do a good job.

2. Aluminium

As discussed many modern caliper use Aluminium Alloy pistons.

They are easy to manufacture, relatively light and hence quite low cost.

The down side is that they expand more than a conventional steel piston TCE is around twice that of conventional steel , they transfer heat easily into the brake fluid HTC is 5 times greater than conventional steel.

They also don't wear very well unless they are hard anodised. This means that they will need to be centreless ground after anodising as the increase in surface roughness caused by this process will make the piston grab the seal and significantly increase piston retraction.

Modern multi-piston calipers with substantially thick pads clearly cope with pistons of this type but old-fashioned designs which have higher caliper piston temperatures may not do quite so well.

My concern with Aluminium pistons and old fashioned calipers concerns the clearance change when the piston expands.

If the piston has an identical size to the steel piston it replaces then as it heats it will increase the radial compression. This will increase pad retraction and in the limit the piston could stick if temperatures became very high.

If cold clearance is increased to eliminate this issue then seals may wear quite quickly if the car is driven gently and the brakes not heated to provide the optimum value.

This is possibly only an issue for race or trackday cars that are hard driven.

I would admit to never have used any aluminium pistons in early 911 calipers.

3. Stainless Steel

This type of piston is typically manufactured from EN303 which is a free-machining Austenitic Stainless Steel and will provide a high standard of surface finish without centreless grinding and good corrosion resistance.

Its HTC is about one third that of conventional steel so the rate at which the brake fluid heats will be slower and this could be a benefit on a race car.

The problem with Austenitic Stainless Steel is that its TCE is similar to Aluminium so it expands by around 70% more than conventional steel and the same seal issues that concern me for Aluminium will not differ greatly for EN303.

There are Martensitic Stainless Steels available but these don't machine as well and would need grinding. The TCE would, however, be the same as conventional steel.

We did buy a batch of Stainless Steel Pistons from a supplier in the USA and had very mixed results. (20 Caliper sets)

Many or them worked well in normal road cars but about 50% of the ones fitted to Race cars stuck during high speed practice and did cause us some difficulty.

This problem is what caused us to look more closely at these issues.

4. Titanium

There are several grades of Titanium available in the market place and the traditional 6AL4V Grade 5 material is the optimum choice.

This alloy has excellent strength, it has a very low HTC - 50% lower than Austenitic Stainless Steel so about 6 times lower than Conventional Steel and 30 times lower than aluminium.

Its TCE is about the same as conventional steel (within 5%) so all seal behaviour should be identical to the original part.

Apart form cost it looks like a good material but it is prone to wear in rubbing seal applications.

The fix for this is to coat the piston and the typical finish is to use a Titanium Carbide applied in a PVD chamber.

This finish is as hard as DLC and provides an extremely smooth surface.

5. Phenolic Resin

This material can be quite hard and have virtually zero HTC but depending on the filler does expand about 4 time more than even aluminium.

It will absorb water and loose strength so the part of the piston outside the dust bot could deteriorate.

I am sure that some materials such as Torlon may work but for small aftermarket quantities the testing needed to be 100% confident would be huge and difficult to justify.

5. Silicon Nitride

It is possible to place silicon Nitride plugs into the cavity in the piston and these will insulate but I have never tired this idea and I am not sure about how 'square' this arrangement would be in practice.

We eventually decided to make our own 6AL4V Titanium Pistons.

they are manufactured on our behalf by a sub-contractor who manufactures pistons for AP Racing.

They are centreless ground polished and Titanium carbide coated and seem to work well.

Sorry to bang on but I hope some detail was worthwhile.”

From:

“I have been interested in caliper pistons for some time now and have been looking at the parts available in the market and tried to reach some conclusions about the 'best' materials.

To start with I think it is important to review the objectives we have with regard to the duty of the brakes and what is required from the pistons.

There is a view that the 'job' of a caliper seal is not only to prevent fluid leakage but to retract the piston when pressure is released as this stops the pad from rubbing on the disc and is good for economy.

I have to say that I don't agree with this analysis and that pad retraction is generally a bad thing and that the effect of this action is similar to 'pad knock off' and increases pedal travel.

It is common to fit race calipers with either residual springs behind the pistons or with low pressure check valves to eliminate this problem.

The seal is always responsible for a small amount of piston retraction and this will vary depending on the surface finish of the piston, the stored energy in the seal due to radial compression and even the fluid used to lubricate the piston during initial assembly.

Using brake fluid, for example, increases seal friction compared to the correct assembly grease and this influence will last for many thousands of miles.

I believe that good quality pistons should have a high level of surface finish, relatively low thermal coefficient of expansion(TCE), Have relatively low Heat Transfer Coefficient (HTC),be relatively corrosion resistant and have good wear resistance.

If we review the materials that have been discussed then the basic properties are easy to find but there are influences that also need to be considered .

1. Conventional Steel

Typically chrome plated, modest expansion, modest heat transfer, huge amounts of comparative test data available and in every sense have stood the test if time.

A conventional medium carbon steel in an 'as rolled' condition is unlikely to have adequate wear resistance.

The quality in terms of dimensional control and surface finish of some aftermarket parts is questionable but Porsche Caliper Pistons supplied by BudWeg seem to be reasonable and do a good job.

2. Aluminium

As discussed many modern caliper use Aluminium Alloy pistons.

They are easy to manufacture, relatively light and hence quite low cost.

The down side is that they expand more than a conventional steel piston TCE is around twice that of conventional steel , they transfer heat easily into the brake fluid HTC is 5 times greater than conventional steel.

They also don't wear very well unless they are hard anodised. This means that they will need to be centreless ground after anodising as the increase in surface roughness caused by this process will make the piston grab the seal and significantly increase piston retraction.

Modern multi-piston calipers with substantially thick pads clearly cope with pistons of this type but old-fashioned designs which have higher caliper piston temperatures may not do quite so well.

My concern with Aluminium pistons and old fashioned calipers concerns the clearance change when the piston expands.

If the piston has an identical size to the steel piston it replaces then as it heats it will increase the radial compression. This will increase pad retraction and in the limit the piston could stick if temperatures became very high.

If cold clearance is increased to eliminate this issue then seals may wear quite quickly if the car is driven gently and the brakes not heated to provide the optimum value.

This is possibly only an issue for race or trackday cars that are hard driven.

I would admit to never have used any aluminium pistons in early 911 calipers.

3. Stainless Steel

This type of piston is typically manufactured from EN303 which is a free-machining Austenitic Stainless Steel and will provide a high standard of surface finish without centreless grinding and good corrosion resistance.

Its HTC is about one third that of conventional steel so the rate at which the brake fluid heats will be slower and this could be a benefit on a race car.

The problem with Austenitic Stainless Steel is that its TCE is similar to Aluminium so it expands by around 70% more than conventional steel and the same seal issues that concern me for Aluminium will not differ greatly for EN303.

There are Martensitic Stainless Steels available but these don't machine as well and would need grinding. The TCE would, however, be the same as conventional steel.

We did buy a batch of Stainless Steel Pistons from a supplier in the USA and had very mixed results. (20 Caliper sets)

Many or them worked well in normal road cars but about 50% of the ones fitted to Race cars stuck during high speed practice and did cause us some difficulty.

This problem is what caused us to look more closely at these issues.

4. Titanium

There are several grades of Titanium available in the market place and the traditional 6AL4V Grade 5 material is the optimum choice.

This alloy has excellent strength, it has a very low HTC - 50% lower than Austenitic Stainless Steel so about 6 times lower than Conventional Steel and 30 times lower than aluminium.

Its TCE is about the same as conventional steel (within 5%) so all seal behaviour should be identical to the original part.

Apart form cost it looks like a good material but it is prone to wear in rubbing seal applications.

The fix for this is to coat the piston and the typical finish is to use a Titanium Carbide applied in a PVD chamber.

This finish is as hard as DLC and provides an extremely smooth surface.

5. Phenolic Resin

This material can be quite hard and have virtually zero HTC but depending on the filler does expand about 4 time more than even aluminium.

It will absorb water and loose strength so the part of the piston outside the dust bot could deteriorate.

I am sure that some materials such as Torlon may work but for small aftermarket quantities the testing needed to be 100% confident would be huge and difficult to justify.

5. Silicon Nitride

It is possible to place silicon Nitride plugs into the cavity in the piston and these will insulate but I have never tired this idea and I am not sure about how 'square' this arrangement would be in practice.

We eventually decided to make our own 6AL4V Titanium Pistons.

they are manufactured on our behalf by a sub-contractor who manufactures pistons for AP Racing.

They are centreless ground polished and Titanium carbide coated and seem to work well.

Sorry to bang on but I hope some detail was worthwhile.”

From:

Why Stainless Caliper Pistons? - Page 2 - Pelican Parts Forums

Because of this? Mine had surface rust around the semi-perimeter and also inside the dome. Is this normal ?

forums.pelicanparts.com

Castrol SRF brake fluid

I've heard good things about this fluid so I decided to try it. I currently use Motul RBF 660 and it works well. The fluid doesn't go dark as quickly as the RBF 600.

RBF 600 left RBF 660 right

Both fluids have about 500 miles on them.

I've heard good things about this fluid so I decided to try it. I currently use Motul RBF 660 and it works well. The fluid doesn't go dark as quickly as the RBF 600.

RBF 600 left RBF 660 right

Both fluids have about 500 miles on them.

Brembo Billet brake master

Another piece of the puzzle for the braking system. I decided to try this before I get the ultimate master the Brembo EVO 17x18. This is the Billet 19x16 which should help with modulation and feel. The billet body should help with feel since there aren't any rough cast spots on the inside of the master. Don't know if us regular people will be able to tell the difference but hey Ill try it.

Racing use only lol

Ti Diet

Weight and measures

Billet master 255g with ti hardware

Stock hardware pin, bleeder, lever bolt and pinch bolts 37g

Ti hardware pin, bleeder, lever bolt and pinch bolts 22g

Another piece of the puzzle for the braking system. I decided to try this before I get the ultimate master the Brembo EVO 17x18. This is the Billet 19x16 which should help with modulation and feel. The billet body should help with feel since there aren't any rough cast spots on the inside of the master. Don't know if us regular people will be able to tell the difference but hey Ill try it.

Racing use only lol

Ti Diet

Weight and measures

Billet master 255g with ti hardware

Stock hardware pin, bleeder, lever bolt and pinch bolts 37g

Ti hardware pin, bleeder, lever bolt and pinch bolts 22g

Last edited:

AEM Ti Wheel Nut and Cone spacer

I got these for my Marchesini wheels. I went with the silver cone spacer this time because it looks like the WSBK setup ha.

Thanks to HKMP7 for the Inspiration

I just ordered the AEM Titanium color cone, I am curious how it looks with my Magnesium wheel

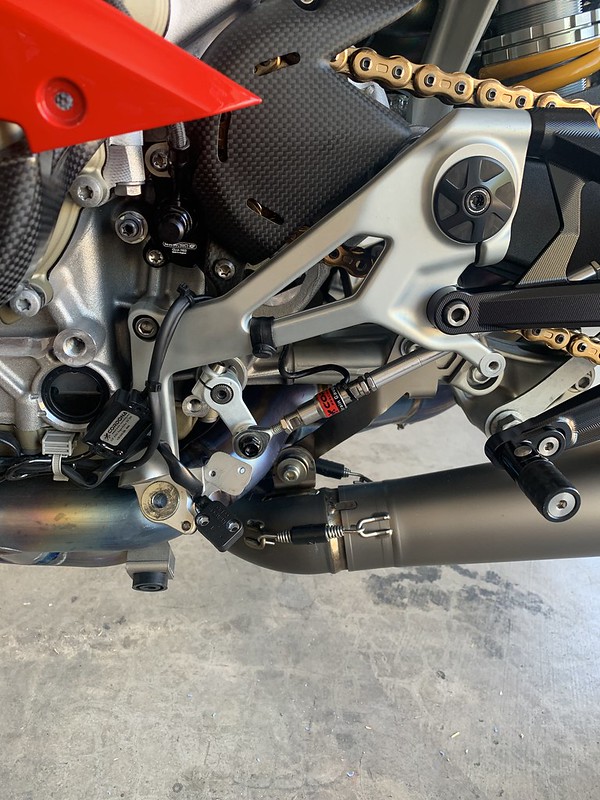

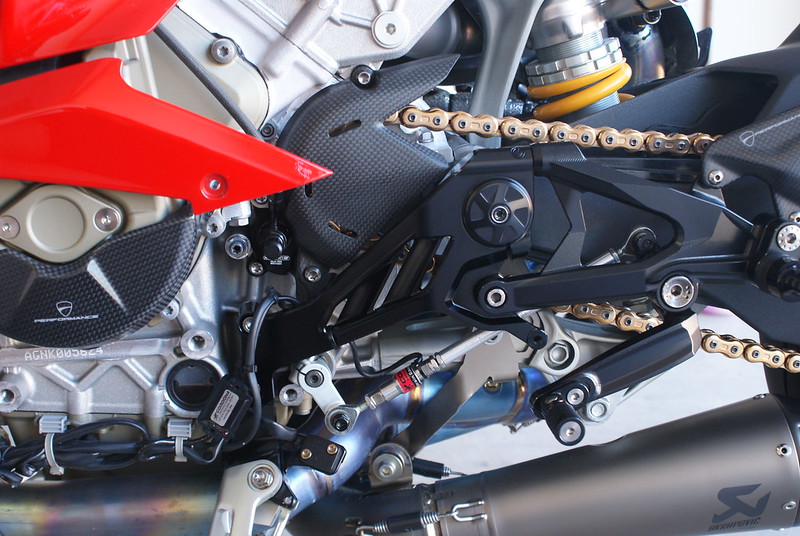

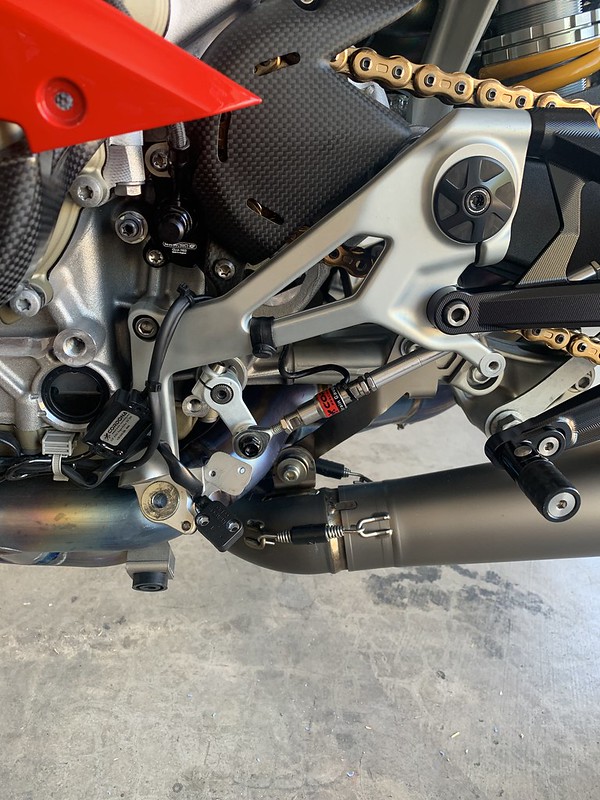

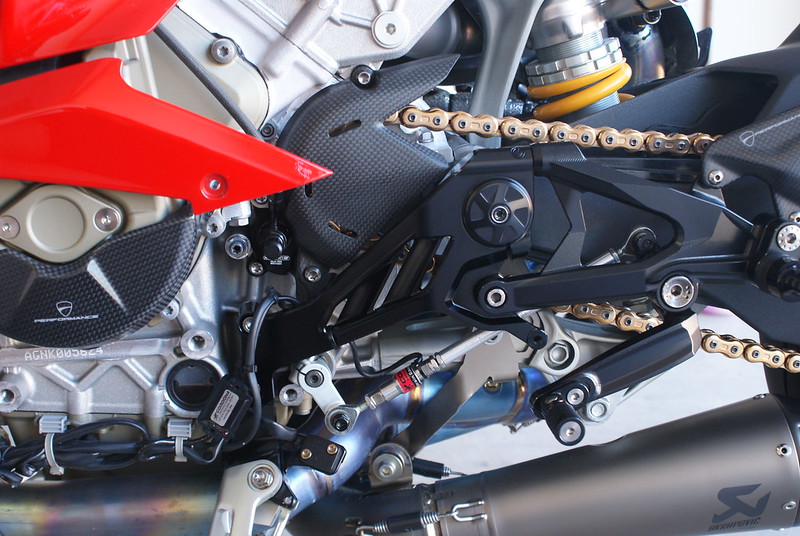

Motocorse side plate install

Pretty straight forward install

Remove these bolts after getting the master cylinder out of the way.

Replace the old and busted with the new Motorcorse hotness. Torque all bolts to 25nm

This side is more involved here are the bolts and cable tie you need to remove

I removed the sidestand first there is a nut on the back of the bolt.

Then unbolt the side stand sensor

Remove the cable tie and rearset

Install the new Motocorse side plate and rearset

If you have these washers behind your factory rearset bracket be sure to re-install them.

Transfer the 2 washers where the sidestand bolt goes. I used grease on the moving parts.

I couldn't find the torque specs for the sidestand sensor so I did it by feel with loctite. All other bolts are torqued to 25nm

Finished product

Weight and measures

Stock brake side plate 155g

Stock shifter side plate 396g

Motocorse brake side plate 154g

Motocorse shifter side plate 483g

Total +86g

We added a small amount of weight but we added a "ton" of style

Pretty straight forward install

Remove these bolts after getting the master cylinder out of the way.

Replace the old and busted with the new Motorcorse hotness. Torque all bolts to 25nm

This side is more involved here are the bolts and cable tie you need to remove

I removed the sidestand first there is a nut on the back of the bolt.

Then unbolt the side stand sensor

Remove the cable tie and rearset

Install the new Motocorse side plate and rearset

If you have these washers behind your factory rearset bracket be sure to re-install them.

Transfer the 2 washers where the sidestand bolt goes. I used grease on the moving parts.

I couldn't find the torque specs for the sidestand sensor so I did it by feel with loctite. All other bolts are torqued to 25nm

Finished product

Weight and measures

Stock brake side plate 155g

Stock shifter side plate 396g

Motocorse brake side plate 154g

Motocorse shifter side plate 483g

Total +86g

We added a small amount of weight but we added a "ton" of style

Last edited:

Your choice of Black Color Motocorse Side Plates with your Black Rear Seat is a PERFECT Match

Also, Thanks so much for the step by step install explanation, will help me a lot

Also, Thanks so much for the step by step install explanation, will help me a lot

Thanks I think it looks awesome I will take more pictures once I put the lowers back on.Your choice of Black Color Motocorse Side Plates with your Black Rear Seat is a PERFECT Match

Also, Thanks so much for the step by step install explanation, will help me a lot

Its super simple you wont have any trouble. The fitment was excellent!