If anyone here interested in LOWERING rear suspension height of your bike for any reason,

I noticed a picture on Instagram, so I contacted Brocks Performance.

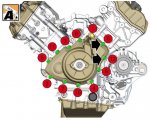

The adjustable link on that picture wa a slightly modified (material removal) of the Brock's Performance lowering kit for Hayabusa: Window Link Kit Adjustable Hayabusa (99-20)

This kit will also need longer bolts.

However, Brock's Performance just told me that they will have a solution specific for our Panigale V4 available in about 2 weeks from that day.

I was excited because my current AELLA lowering link is NOT adjustable. However, then I realized, that the Instagram picture below shows a Panigale V4 with the optional Akrapovic full race/slip on system.

That is why it is easy to reach the adjustment bolts.

On my bike with the type approved Akrapovic (shape like stock silencer), the link would be half covered by the silencer,

meaning if I want to adjust the right height, I will have to remove the silencer (and we all know that is not the easiest thing to do with our bike).

So I think I will just have to be happy with my NON Adjustable AELLA lowering link, but I thought I should share about this product in case anyone here interested in lowering their bike.

Brock's Performance also informed me that they are also working on possible solution to RAISED the bike. Just contact them directly, they are very fast in responding to your inquiry.

And here is their solution for Panigale V4 (to lower the bike) ready to purchase at their website:

Lowering Links

They even offer a version with Titanium Bolts/Hardware:

Window Link Kit Adjustable Panigale V4 / S / Speciale (18-20) w/ Titanium Bolts

I noticed a picture on Instagram, so I contacted Brocks Performance.

The adjustable link on that picture wa a slightly modified (material removal) of the Brock's Performance lowering kit for Hayabusa: Window Link Kit Adjustable Hayabusa (99-20)

This kit will also need longer bolts.

However, Brock's Performance just told me that they will have a solution specific for our Panigale V4 available in about 2 weeks from that day.

I was excited because my current AELLA lowering link is NOT adjustable. However, then I realized, that the Instagram picture below shows a Panigale V4 with the optional Akrapovic full race/slip on system.

That is why it is easy to reach the adjustment bolts.

On my bike with the type approved Akrapovic (shape like stock silencer), the link would be half covered by the silencer,

meaning if I want to adjust the right height, I will have to remove the silencer (and we all know that is not the easiest thing to do with our bike).

So I think I will just have to be happy with my NON Adjustable AELLA lowering link, but I thought I should share about this product in case anyone here interested in lowering their bike.

Brock's Performance also informed me that they are also working on possible solution to RAISED the bike. Just contact them directly, they are very fast in responding to your inquiry.

And here is their solution for Panigale V4 (to lower the bike) ready to purchase at their website:

Lowering Links

They even offer a version with Titanium Bolts/Hardware:

Window Link Kit Adjustable Panigale V4 / S / Speciale (18-20) w/ Titanium Bolts