The titanium pistons for my GP4-MS that I bought from MCET also have holes drilled on them.

It also came with DLC (Diamond Like Carbon) coatings.

Here is the webpage link to the MCET website:

caliper piston titanium for Brembo GP4 MS calipers

The picture below is my own titanium caliper piston (MCET) that I keep for my future 108mm GP4-MS with cooling fins.

And below is the picture of the BrakeTech stainless steel piston.

The Braketech Stainless Steel Piston does have a cleverly designed backside with a scalloped area, which further help reduce the weight a bit and has a bit more volume for brake fluid.

From BrakeTech website:

https://braketech.com/caliper-racing-pistons/

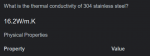

However, according to the webpage above, BrakeTech points out that the main advantage of the Stainless Steel Piston compared to the Aluminum Piston is thermal Conductivity.

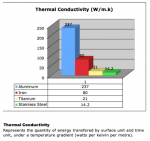

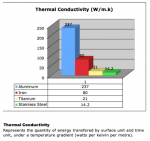

But Braketech did not address any advantage of Stainless Steel compared to Titanium except for the small thermal conductivity advantage in this graph I screenshot from the Braketech website below:

The graph above shows Titanium has a bit more thermal conductivity compared to Stainless Steel. The difference is only 21-14.2 = 6.8, which is nothing compared to the 237 of aluminum but wait...

we need to do more research... we cannot just accept any value shown on a brochure because the devil is in the details.

Please remember the grade of Titanium used also affects the thermal conductivity, and I noticed Braketech also did not specify the grade of Stainless Steel they use. They only say their stainless steel is proprietary. But was it 316 or 304 or other grades?

Because of the number of sales for this brake caliper piston, there is not enough economy of scale for super proprietary stainless steel. So most likely, it must be some commercially available grade of stainless steel on the market.

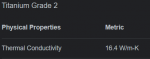

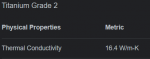

For example, Titanium Grade 2 has a thermal conductivity of:

This means Titanium Grade 2 has basically the same Thermal conductivity as Stainless Steel (table below)

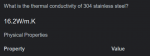

While the Titanium Grade 5 normally used for all the bolts/screws on our motorcycle (ProTi/ProBolt) (and presumably also for the titanium pistons from MCET) has an even lower thermal conductivity of just:

Yes, so from a THERMAL CONDUCTIVITY point of view, we can call Titanium and Stainless Steel evenly match, or if we use Titanium Grade 5, it could have just 40% of the 316/304 Stainless Steel thermal conductivity, which means Titanium is a BETTER material for thermal conductivity then stainless steel.

But what really jumps out from my quick research is the fact that

Titanium has a lower coefficient of thermal expansion than stainless steel.

If you heat titanium, it will expand less than stainless steel.

Since Caliper Pistons require it to be machined precisely for a TIGHT FIT (prevent leak of brake fluid that could be a catastrophe) but still loose enough to prevent stickiness of movement with friction from the caliper seal,

Then for the caliper piston, Titanium material will have an advantage because at the most extreme heat range during racing (by professional racers), the stainless steel would expand more than titanium.

The MCET Titanium piston also has another advantage in the form of DLC coating, which helps with less friction against the caliper seal.

The Brembo GP4-RR (or higher grade) uses a TIN coating just like Ohlins forks to also help reduce friction against the caliper seal and move smoother.

Don't get me wrong, the Braketech stainless steel piston is cleverly engineered and has a better price point, possibly even more bang for the buck for the nonprofessional racer.

But if you want the ultimate, Titanium Piston is still the choice.

There are reasons why the higher-end brake calipers like GP4-RR (and higher grade) use Titanium Brake Pistons (which cost more) than stainless steel.

So, if you still have the Titanium Pistons from MCET, I recommend you swap the BrakeTech Stainless Steel piston with the Titanium Pistons from MCET for your GP4-MS.

, meaning my 998 will not have a brake caliper until next year

, meaning my 998 will not have a brake caliper until next year  ...

...