I think the issue is more to do with the threads in the aluminium frame rather than the M8 steel bolts.

No, if you check the ProTi Titanium M8 bolt page link here:

https://www.protiglobal.com/good.php?fid=1408&column=M8+Bolt&column1=BOLT

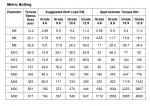

You can see the maximum safety torque is rated at 38Nm. The ProTi Titanium Bolt is made from Grade 5 Titanium and then fully FORGED, which allows them to be equivalent to Grade 10.9 steel bolts.

Even with the equivalent strength of Grade 10.9 steel, ProTi Titanium Bolt only recommends max safety torque at 38Nm.

For a second reference, below is a table of recommended Max Torque for STEEL material bolts along with the corresponding grade, and as you can see for M8 with Grade 10.9, max Torque is 38.7Nm (so the ProTi limit is spot on)

Once you torque a bolt near it's limit, it will STRETCH almost or at its stretch limit, so if you reuse, it might fail (especially under load).

The threads on the aluminum frame (and especially the aluminum cylinder head) should be stronger since they are part of a larger mass/structure, and they also have a larger diameter than the M8 bolt, 8mm diameter, so they will not stretch as much as the bolt.

But it's also true that the 2 bolts going to the aluminum frame are only recommended to 31Nm not only because of the aluminum material of the frame but also how the frame was cast compared to the aluminum cylinder heads (where the other 2 bolts torqued to 35Nm)

I was not happy with my 2018 Panigale V4 Service Manual because I worried it was too outdated,

so last night, I decided to purchase the service manual specific for my 2020 V4 25° Anniversario 916, and below is the screenshot from my bike model (2020) service manual related to these subframe bolts.

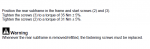

These 2020 V4 25° Anniversario 916 specific manual still recommends replacing all 4 subframe bolts after removal/refitting.

From these 2020 V4 25° Anniversario 916 service manual, the 2 bolts that connect to the cylinder head are torqued at 35Nm, which is very close to the max limit of 38Nm (and with variation/inaccuracy in torque wrench might be exceeded in some cases).

You might ask, then, why do the 2 other bolts going to the aluminum frame recommended for 31Nm also need to be replaced?

Well, all 4 bolts are using the same Part# 7791B321AA. Once you take all 4 of them out from the bike, you might mixed them and forget which one came from the 35Nm (lower bolts to the cylinder head) and which came from the 31Nm (upper bolts), so to make sure Ducati just recommend replacing all 4 bolts.

Not to mention, All 4 bolts need to hold on average, 200 pounds of rider weight (or 350 pounds of rider and passenger weight when there are passengers) plus the weight of the subframe itself. So these 4 bolts experience continuous stress.

Plus these service manual also ask to use GREASE B, meaning that 35Nm and 31Nm is WET TORQUE and not DRY TORQUE. Most max torque ratings on the tables are DRY TORQUE. So the 35Nm GREASED Torque is higher if you correlate it to Dry Torque.

Another IMPORTANT clue that this bolt Part# 7791B321AA needs to be Torqued BEYOND other M8 bolts is the fact that Ducati chose a TORX head instead of the regular hex socket, as you can see from the picture of the exact bolt below.

I cannot recall any other M8 bolts with a TORX head in my bike besides these 4 subframe bolts. Even the rear set bolts with M8 only have the regular hex socket, and these hex socket types only tighten to around 25Nm.

TORX head designed can handle more torque than hex socket head due to more surface area to transfer the torque.

In summary, the more I think about this, and based on Ducati's choice to use a TORX head for these 4 bolts, I believe the Akrapovic Manual might have mistake in assuming it is just M8 bolts where normally it will only be tightened to around 25Nm. To my surprise, the Akrapovic manual doesn't even say anything about using GREASE B.

So, I now strongly believe the correct torque for the 4 bolts holding the subframe should be 35Nm for the lower bolt to the cylinder head and 31Nm to the main frame with GREASE B. The Akrapovic manual is incorrect.

The price of these Part# 7791B321AA M8 TORX head special bolt is only 3.53 euro at

7791B321AA Ducati Spezialschraube - KFM-Motorräder or $6.62 at Ducati Omaha:

7791B321AA - SCREW, SPECIAL per bolt

So for a total of less than 16 Euro at KFM or less than $27 USD at Ducati Omaha, it's worth it to follow the Ducati Service Manual, replace them with 4 brand new bolts, and torque them to 35Nm and 31Nm with GREASE B whenever you take them out.